Bent Actuating Bars

When the end of a ultra light motor cracks or breaks off the cause is most likely the result of a bent actuating bar. When any type of restriction is encountered the actuating bar will bend. Whether the bend is small or large, over time the bend will put stress on the motor and the end of a ultra light motor will crack and may break off.

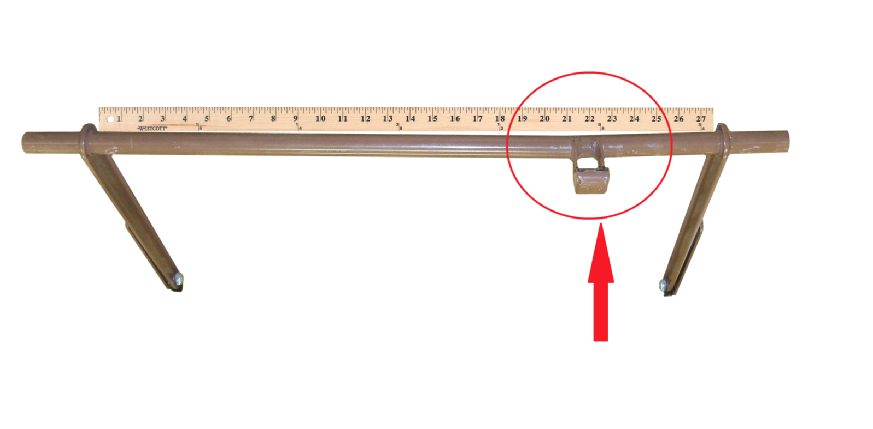

Some bends are very obvious.

And some are not. To check for a bent actuating bar a 27.5" straight edge and 90 degree square is needed.

Place the straight edge across various section of the actuating bar between the welded spring deck connecting bars.

If there is a bend it will most likely to occur at the motor tab.

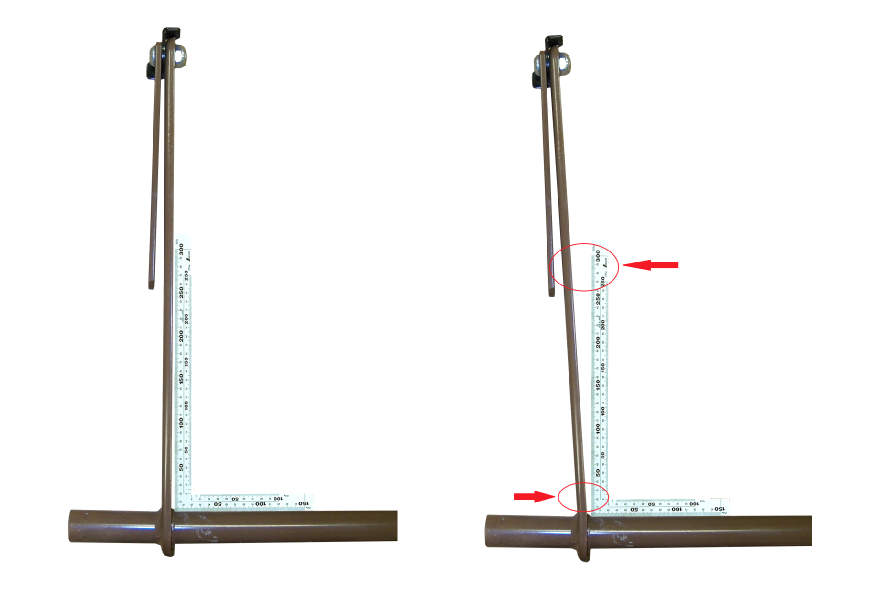

If a bend is not detected then the next step is to verify the that welded spring deck connecting bars are perpendicular to the main bar, using square or similar item. Place the square on the main bar and slide it as close as possible to the weld spring deck connecting bar. Because of the weld the square cannot be brought flush against the spring deck connecting bar, but any bends should be easily detected.

If any bend is detected, replace the actuating bar.

Home

Home